Category

NSK High Precision Factory Price 51214 Thrust Ball Bearing

Keywords:

Category:

Thrust Ball Bearings

NSK High Precision Factory Price 51214 Thrust Ball Bearing

Detail

Structure:

The thrust ball bearing is composed of race,shaft washer and steel ball retainer.The one that matches with the axis is called washer.The one that matches with the shell is called the ring.

Thrust ball bearing is a kind of separation bearing. The shaft ring and seat ring can be separated from the cage and steel ball components.

Thrust ball bearing is designed to withstand thrust load at high speed and is composed of a gasket-shaped ring with a ball rolling groove.Owing to its cushion-shape ring,the thrust ball bearing is divided into flat-base cushion type and aligning spherical surface cushion type.

There are two key points in the assembly of thrust ball bearings. One is the control of the pressing quality of the cage and the steel ball, and the other is the control of the nominal height T after the assembly of the bearing. In addition, since the shaft ring and the seat ring can be separated, there is a management problem. It is to prevent the mixing of imported bearing parts. The M-type press cage uses a curved edge assembly die. After pressing, the steel ball is required to rotate flexibly in the pocket hole, but it can not fall off from the pocket hole, and the technical procedure to check the momentum of the steel ball in the pocket hole. If the solid cage is imprinted too deeply, the momentum of the steel ball will be small, and the connection between the embodiments and the cage is too little and the strength is insufficient, which is easy to fall off and cause the cage to be scrapped.

Small thrust ball bearing seat ring and shaft ring inner diameter size difference is very small, there is no obvious difference between the two bundles. In order to prevent the phenomenon of mixed sleeves, that is, a set of bearings installed are found to be both seat rings or shaft rings. This requires certain measures. Usually, the drawing ring and the seat group are distinguished by auxiliary tooling when the set is closed, or the inner diameter plug gauge is used to check the inner diameter size before sampling the nominal height. In order to check the inner diameter, the seat ring is placed below and the shaft ring is placed above. If the inner diameter of the seat has obvious quenching heating oxidation color or is not grinding, there is no need to test the inner diameter size, and the difference between the shaft ring and the seat can be clearly seen, and it is not easy to mix. After assembling the thrust ball bearing, the nominal height T should be measured to confirm whether it is qualified. When measuring, calibrate with height block or standard parts, and measure the load, the bearing needs to rotate dozens of times, and be sure to reach the minimum height.

CUSTOMER VISIT

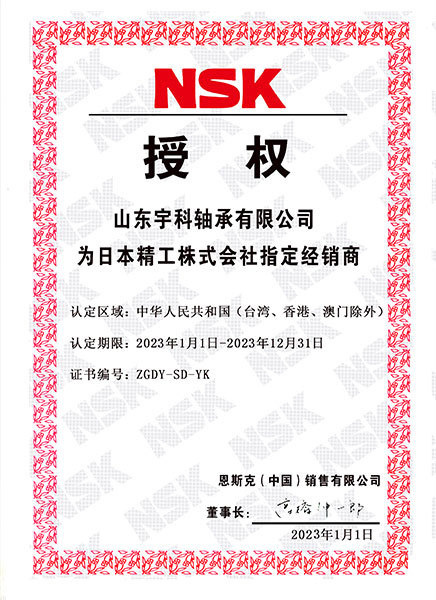

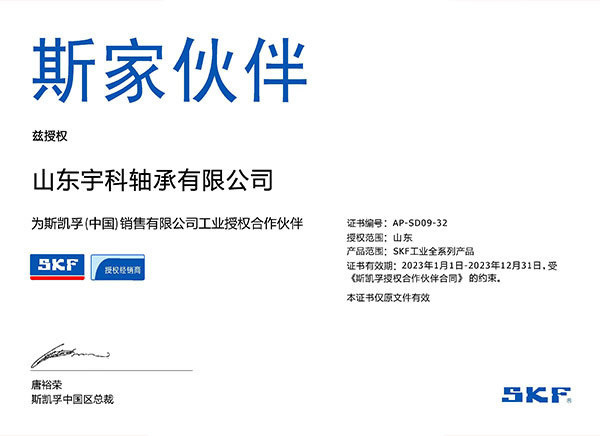

CERTIFICATE

EQUIPMENT

PARTNER

Online consultation

RELATED PRODUCTS