Category

NSK Professional Manufacturer Supply 538/800K Spherical Roller Bearing

Keywords:

Category:

Spherical Roller Bearing

NSK Professional Manufacturer Supply 538/800K Spherical Roller Bearing

Detail

SPHERICAL ROLLER BEARINGS

Spherical roller bearings consist of a common spherical raceway outer ring and two rows of spherical rollers between the double raceway inner ring. The spherical roller bearings is self-aligning, and can automatically adjust the misalignment caused by the deflection or misalignment of the shaft or bearing seat, and the allowable alignment angle is 1~2.5 degrees. Spherical roller bearings can bear radial load, bidirectional axial load and its combined load, especially the radial load capacity is large, and it has good anti-vibration and impact resistance. It is widely used in iron and steel metallurgical equipment, mining equipment, cement machinery, paper machinery, ships, coal mills, petroleum machinery, engineering machinery, etc.

Installation method:

The inner hole of the spherical roller bearing has two installation methods: cylindrical and conical, and the conical tapered hole is 1:12 and 1:30. By unloading the sleeve, the bearing can be installed on the optical shaft or stepped shaft conveniently and quickly. The cylindrical inner hole can also be installed on the tapered shaft with an inner taper sleeve.

Materials

Bearing rings and rolling elements can be made of a number of different materials, but the most common is "chrome steel", (high carbon chromium) a material with approximately 1.5% chrome content. Such "chrome steel" has been standardized by a number of authorities, and there are therefore a number of similar materials, such as: AISI 52100 (USA), 100CR6 (Germany), SUJ2 (Japan) and GCR15 (China).

Some common materials for bearing cages:

- Sheet steel (stamped or laser-cut)

- Polyamide (injection molded)

- Brass (stamped or machined)

- Steel (machined)

The choice of material is mainly done by the manufacturing volume and method. For large-volume bearings, cages are often of stamped sheet-metal or injection molded polyamide, whereas low volume manufacturers or low volume series often have cages of machined brass or machined steel. For some specific applications, special material for coating (e.g. PTFE coated cylindrical bore for vibratory applications) is adopted.

CUSTOMER VISIT

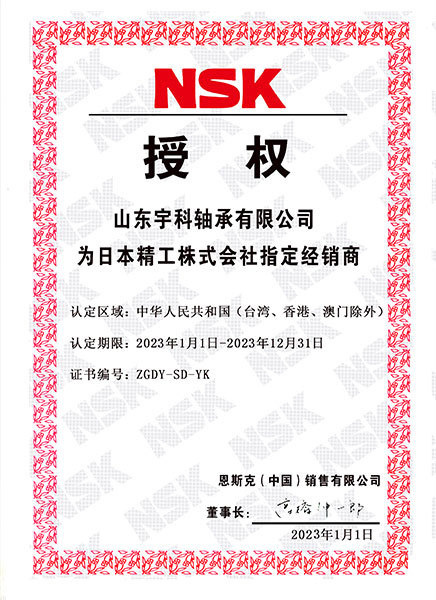

CERTIFICATE

EQUIPMENT

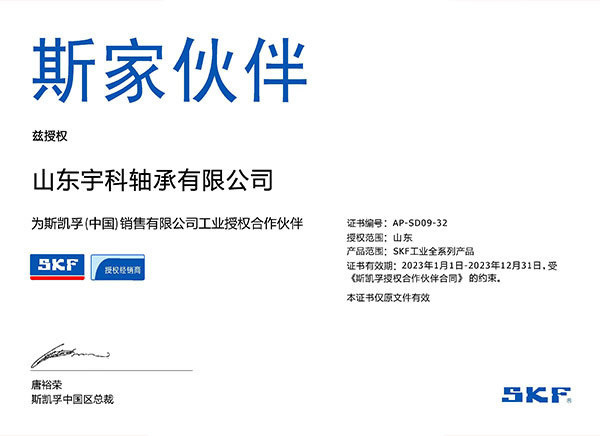

PARTNER

Online consultation

RELATED PRODUCTS