Category

Bearing Supplier Double Row KOYO HM.265049-90068 Inch Taper Roller Bearing

Keywords:

Category:

Tapered Roller Bearings

Bearing Supplier Double Row KOYO HM.265049-90068 Inch Taper Roller Bearing

Detail

|

Product name |

Bearing Supplier Double Row KOYO HM.265049-90068 Inch Taper Roller Bearing |

|

Bearings Feature |

1 Long life span 2 low rotation&impact resistance&vibration resistance |

|

Material |

Chrome Steel |

|

Bearing Package |

Pallet,wooden case,commercial packaging or as customers' requirement. |

|

Service |

OEM service provided |

|

Delivery time |

3-15 days depends on quantity needed |

What types of loads can tapered roller bearings handle?

The angled and tapered shape of tapered roller bearings minimizes the stress caused by a combination of radial and axial loads. Radial and axial loads often combine to create different loads upon a bearing assembly. The ability to handle angular loads and changing angular loads – makes tapered roller bearings indispensable to various technical designs and industries. The tapered shape essentially concentrates radial and axial loads into a unified load that is more easily harnessed. Which angular loads can be harnessed depends on the precise angle of the tapered bearing. They can harness a comprehensive range of forces by configuring two or even more tapered bearings.

The steepness of the roller bearing's gradient increases the thrust/axial load it can handle, while a shallow angle increases the radial load capacity. As the radial load increases, the bearing experiences more stress against the sides of the bearing raceways. A more shallow angle minimizes stress, reducing pressure on the rollers. Increased axial load contributes to the stress applied to the top of the rollers. A steeper angle will distribute the pressure more towards the center of the bearing and less onto the rollers themselves.

Common uses of tapered roller bearings

A tapered roller bearing is appropriate wherever a bearing must handle combination loads. One of the most common uses is maintaining axial balance, achieved with multiple tapered roller bearings along an axle or shaft. The tapered bearings will evenly distribute loads when adequately aligned, minimizing wear and tear on the components. With higher surface area, tapered roller bearings can distribute friction and heat from combination loads more efficiently than non-tapered rollers (which are more efficient than tapered bearings only with the most straightforward non-combination forces). This reduced friction increases the rotational speed of interfacing parts and makes tapered roller bearings ideal for use in:

- Engines

- Motors

- Gearboxes (especially those with helical gears)

- Wheels & axles

- Turbines & propellers

This equipment must combine many different angles and utilize them to drive motors, driveshafts, and other rotational components.

CUSTOMER VISIT

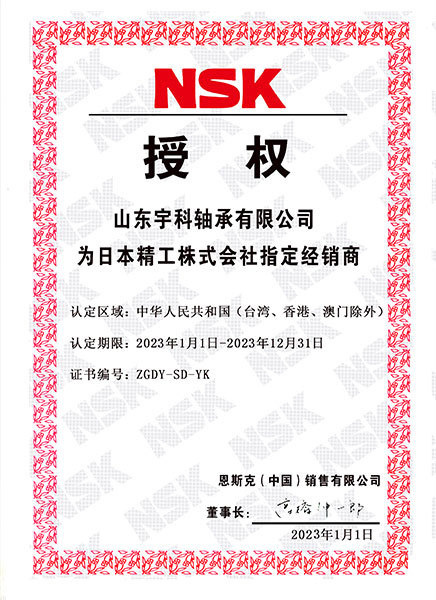

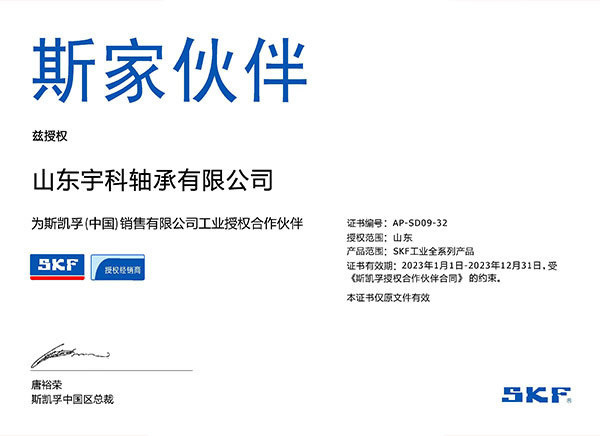

CERTIFICATE

EQUIPMENT

PARTNER

Online consultation

RELATED PRODUCTS