Category

NSK 7032AC Angular Contact Ball Bearing For Machine Tool Spindle

Keywords:

Category:

Angular Contact Ball Bearings

NSK 7032AC Angular Contact Ball Bearing For Machine Tool Spindle

Detail

Bearing description:

Single row angular contact ball bearings can only withstand axial load in one direction. When such bearings are subjected to pure radial load, they must be installed and used in pairs because the line of action of the rolling body load and the line of action of the radial load are not in the same radial plane, resulting in an internal axial component.

Design features:

Single row angular contact ball bearings can only withstand axial load in one direction. When such bearings are subjected to pure radial load, they must be installed and used in pairs because the line of action of the rolling body load and the line of action of the radial load are not in the same radial plane, resulting in an internal axial component.

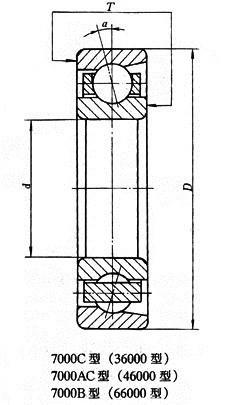

Structure form:

1. Separation type angular contact ball bearing

This bearing code is S70000, its outer ring roller side has no lock, can be separated from the inner ring, cage, ball assembly, so can be installed separately. This kind of micro bearing with inner diameter less than 10mm is used for gyro rotor, micro motor and other devices that have higher requirements for dynamic balance, noise, vibration and stability.

2. Non-separated angular contact ball bearings

The ring groove of this kind of bearing has a lock, so the two rings can not be separated. It can be divided into three types according to the contact Angle:

① Contact Angle α=40°, suitable for bearing large axial load;

② Contact Angle α=25°, mostly used for precision spindle bearings;

③ Contact Angle α=15°, mostly used for large size precision bearings.

3. Configure angular contact ball bearings in pairs

Angular contact ball bearings configured in pairs are used for bearing both radial load and axial load, and can also bear pure radial load and axial load in any direction. This kind of bearing is provided to the user by the manufacturer according to certain pre-load requirements. When the bearing is installed on the machine, the clearance in the bearing is completely eliminated, and the ring and the ball are in a pre-tightening state, thus improving the steel of the combination bearing.

There are three different configuration types of paired angular contact ball bearings:

(1) back-to-back configuration, after code DB(such as 70000/DB), this configuration has good rigidity, good performance under overturning moment, bearing can withstand two-way axial load;

(2) face to face configuration, after code DF(such as 70000/DF), this configuration of rigidity and ability to withstand overturning moment is not as good as DB configuration, bearing can withstand two-way axial load;

(3) Series configuration, after the code DT(such as 70000/DT), this configuration can also series three or more bearings at the same support, but can only bear a single direction of the axial load. Usually, in order to balance and limit the axial displacement of the shaft, the other support shall be equipped with a bearing capable of bearing the axial load in the other direction.

In addition, a single row angular contact ball bearing is available for any pairing. This kind of bearing is specially processed and can be combined in any way such as two back-to-back, two face to face or two in series. The axial clearance of pairing combination can be selected according to needs. The post code CA means the axial clearance is small, CB means the axial clearance is moderate, and CC means the axial clearance is large.

Universal matching bearings can also be configured into bearings with pre-interference according to the requirements of use, and the code GA, GB, GC. GA represents small preinterference after pairing. GB indicates moderate preinterference after pairing; GC indicates a large preinterference after pairing.

CUSTOMER VISIT

CERTIFICATE

EQUIPMENT

PARTNER

Online consultation

RELATED PRODUCTS