Category

Automobile Bearing IKO Brand NA4928 Needle Roller Bearing

Keywords:

Category:

Needle Roller Bearings

Automobile Bearing IKO Brand NA4928 Needle Roller Bearing

Detail

|

Specification |

|

|

Product name |

Needle Roller Bearings |

|

Brand |

WSRY or Customization |

|

Material |

GCr15; Chrome Steel; Stainless Steel |

|

Precision grade |

P0,P6,P5,P4,P2 |

|

Certification |

ISO9001:2015 |

|

Application area |

Military industry, automobile manufacturing, robotics, national defense, new energy, aerospace, home appliances, etc |

|

Quality |

100% Tested |

|

Feature |

High precision; High speed; Long service life |

|

Package |

OEM Customized |

Needle Roller Bearings (needle bearing) is a cylindrical roller with roller bearings, relative to its diameter, roller both thin and long. This is called needle roller. Despite having a smaller cross-section,has a higher load bearing capacity, equipped with a thin and long needle bearing roller (roller diameter D≤5mm,L / D≥2.5, L is the length of the roller), so radial structure is compact, its diameter size and load capacity and other types of bearings, minimum diameter, especially for radial dimensions limited support structure.

What are the common needle roller bearing failures?

Type of failure:

(1) bearing rotation is difficult and heating

(2) bearing operation has abnormal sound

(3) bearing vibration

(4) Inner seat ring spalling and cracking

(5) Outer seat ring spalling and cracking

(6) Bearing raceway and rolling body produce indentation

What are the disassembly methods of needle roller bearings?

1、Method of percussion

The knocking force is generally added to the inner ring of the bearing. The knocking force in the shielding room should not be added to the rolling body and retaining frame of the bearing. This method is simple and easy to use, but it can easily damage the bearing. The application of this method should pay attention to the placement of the pad should be appropriate, the point of emphasis should be correct.

2、Hot separation process

Used to remove tight fit bearings. First, the oil heated to about 100℃ is poured on the bearing to be removed with an oil can. After the bearing ring is heated and expanded, the bearing can be pulled out with a tension tool.

3、Push and press method

Press the bearing, stable and reliable work, no damage to the machine and bearing shielding machine room. The press has manual press, mechanical or hydraulic press press. Note: The pressure point of the press should be on the center of the shaft, and the pressure should not be biased.

4、Pull out method

Special tension, disassembly, as long as the rotation of the handle, the bearing will be slowly pulled out. When removing the outer ring of the bearing, the Angle of the two legs of the puller should be opened outward; When disassembling the bearing inner ring, the two feet of the puller should be inward and stuck on the end face of the bearing inner ring.

CUSTOMER VISIT

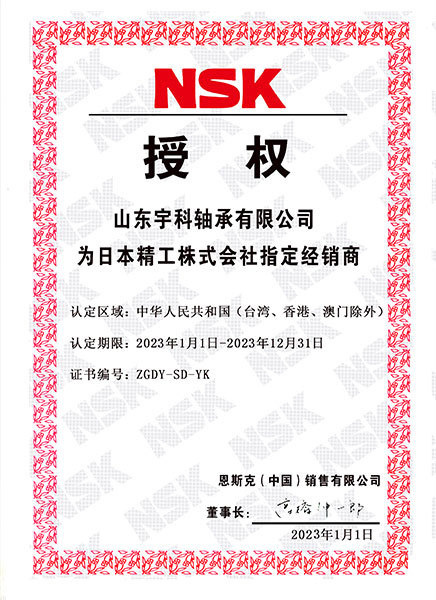

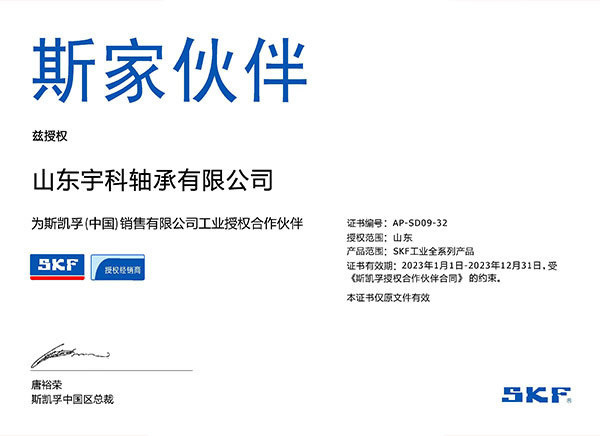

CERTIFICATE

EQUIPMENT

PARTNER

Online consultation

RELATED PRODUCTS