Category

Factory Price Bearing Wholesale 6205-2RS Deep Groove Ball Bearing

Keywords:

Category:

Deep Groove Ball Bearings

Factory Price Bearing Wholesale 6205-2RS Deep Groove Ball Bearing

Detail

Single Row Deep Groove Ball Bearings are widely used in household appliances, toys, electric power tools, car motors and other fields. With optimal design, high reliability heat treatment, precision manufacturing processes and high-grade grease, these products perform better on reliability, vibration and noise levels than standard products making them more suitable for electric motor applications. These products can also be applied to most gearbox applications as well.

Deep groove ball bearing is the most common type of rolling bearing.

The basic type of deep groove ball bearing consists of an outer ring, an inner ring, a group of steel balls and a group of cages. There are two types of deep groove ball bearing, single row and double row, deep groove ball structure is also divided into sealed and open two kinds of structure, open refers to the bearing without sealing structure, sealing type deep groove ball is divided into dust seal and oil seal. The dust proof sealing cover is made of steel plate stamping, which only prevents dust from entering the bearing raceway. The oil-proof type is contact oil seal, which can effectively prevent the grease spillover in the bearing.

Deep groove ball bearings are the most widely used bearing type and are particularly versatile. They have low friction and are optimized for low noise and low vibration which enables high rotational speeds.

Deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls and a set of cages.

It mainly bears pure radial loads, but also can bear joint loads. When it is subjected to pure radial load, its contact Angle is zero. When it has a larger radial game, that is, it has angular contact bearing performance, which can withstand a larger axial load. Deep groove ball bearing has small friction coefficient and high limit speed, so it has more advantages than thrust bearing when axial load is rotating at high speed. But because its aligning performance is limited, the concentricity of bearing installation should be high, otherwise it will affect the balance of its operation, increase the bearing stress, and thus shorten the working life.

Deep groove ball bearing simple structure, compared with other easy to achieve high precision, so can be mass production. In addition to the conventional models, it also has a variety of structural variations, such as deep groove ball bearing with dust cover, deep groove ball bearing with rubber ring and deep groove ball bearing with a stop groove and so on.

What is the processing process of deep groove ball bearing?

Processing process steps of deep groove ball bearing:

1.tube blank processing: the bearing steel is heated to 1150℃ ~ 1200℃ in the heating furnace, and the perforator is used to perforate the heated tube blank to make capillary tube;

2.spheroidizing annealing: the tubular spheroidizing annealing, the hardness range of the annealed tubular is HRB88 ~ 94;

3.Hot rolling of tube billet: send the annealed tube into the heating furnace for secondary soaking heat; The waste pipe is formed by diameter reduction, wall reduction and extension rolling of the tube after secondary heat soaking.

4.tube blank shaping and cutting: the waste pipe through the sizing unit, sizing and shaping, and then straightening and cutting, forming a suite;

5.recrystallization annealing: the kit will be recrystallization annealing treatment, eliminate work hardening, so as to facilitate the implementation of cold rolling;

6.Soft grinding kit: The double end face of the kit is first softened, then the outer circle of the kit is softened, the double end face is first grinded, then the outer circle is grinded. The outer circle is a through grinding, and the material is processed together through the end face to ensure that the outer diameter of the part is always on the same plane with the support plate, the outer diameter taper is ensured within the control range, the Angle relation between the two grinding wheels in the double end grinding process is adjusted, and the parallel difference of the end face is controlled. The precision of the end face is used as the datum of the post-process processing; The outer circle is processed by centerless grinding.

7. Kit fine hole: drill the stop bolt hole and oil hole on the kit surface and rough the inner hole surface of the kit to prepare for cold rolling inner hole surface;

8..Cold rolling kit: For cold rolling of deep groove ball bearing ring groove, the feed speed of the core roller in the process of cold rolling has six stages, the speed range is 0.4mm/s ~ 1.0mm/s, and the track of the speed curve in a processing cycle is fast, slow, slow, until stop; The rolling time was between 6s and 14s, and the rolling pressure was 80KN;

9.Turning kit: chamfer the kit and seal the groove;

10.fine grinding kit: fine grinding kit, improve the surface accuracy of the kit;

11. installation of bearings: between the ring into the ball, install the cage, grease, install seals, complete the assembly of deep groove ball bearings.

CUSTOMER VISIT

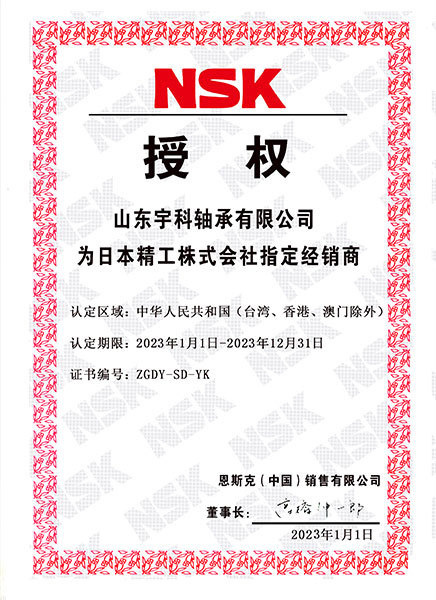

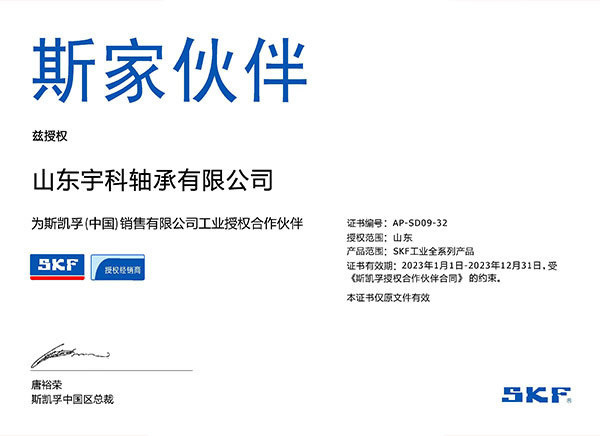

CERTIFICATE

EQUIPMENT

PARTNER

Online consultation

RELATED PRODUCTS